SCOPE OF WORKS

Regulatory Exhaustive Visual Inspection

Regulatory Exhaustive Visual Inspection

Infrared Thermal Imaging (Hotspot Detection)

Infrared Thermal Imaging (Hotspot Detection)

Ultraviolet Inspection (Corona & Partial Discharges)

Ultraviolet Inspection (Corona & Partial Discharges)

Corrosion Inspection (Nace/Frosio)

Corrosion Inspection (Nace/Frosio)

Earthing Works Measurement

Earthing Works Measurement

Surge Arresters Testing (Hotline)

Surge Arresters Testing (Hotline)

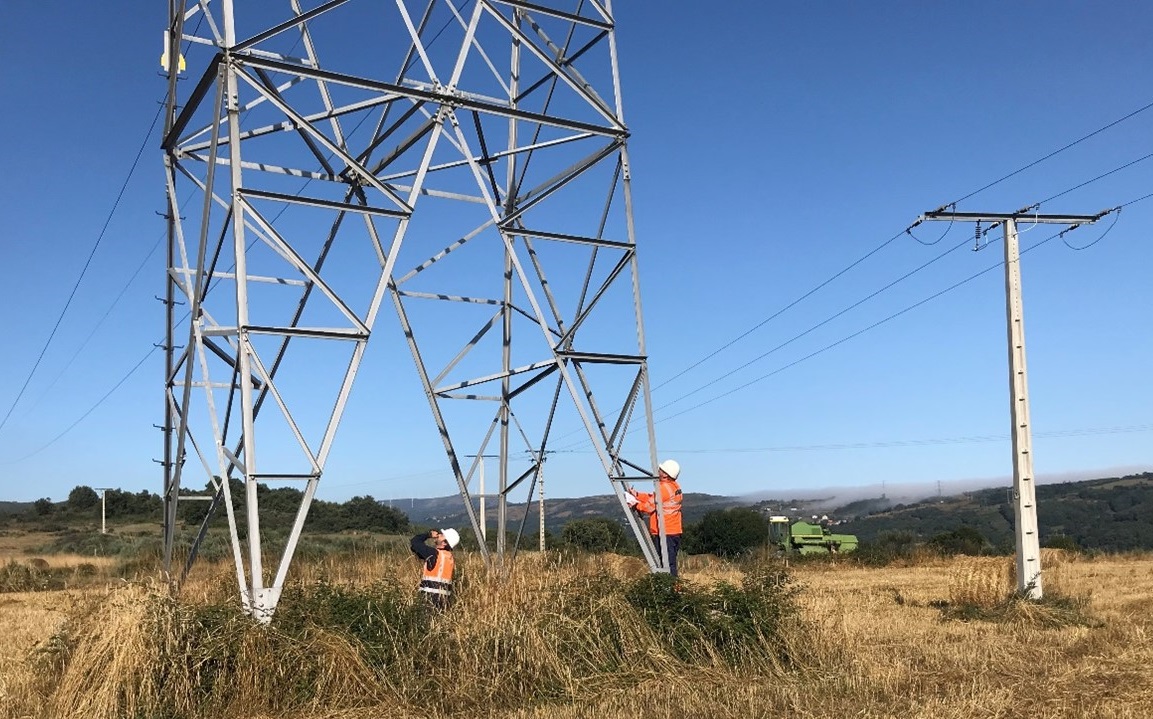

High Line Division S.L. is a pioneer company in the implementation of the latest technologies and state of art for the development of technical inspections of high voltage installations. From one side, we have developed specific procedures for carrying out exhaustive inspections in compliance with national regulations using checklists, where all anomalies and their levels of severity are recorded, developing inspection methods that are essential for the correct preventive maintenance of the facilities, such as performance monitoring of the insulation and surge arresters in hotline, earthing works measuring without the need of disconnecting from the structures, or network monitoring systems in real time.

On the other side, developing our own integrations to provide solutions to the specific needs of the industry, such as exhaustive visual inspections integrating visual, thermal and corona sensors. Testing and verification of surge arresters and insulation in hotline without the need for destructive laboratory tests by studying their electric field in real time. Topographic surveys or even installation of bird diverters on high voltage overhead lines in service, which shows our degree of commitment to the industry.

With the intention of providing a solution to the need to carry out aerial inspections within spaces with reduced mobility and in the presence of energized elements, the Engineering and Drones Department of High Line Division has developed an integration at the end of a telescopic insulating Hotstick similar to that used in drones.

EXHAUSTIVE VISUAL INSPECTION

Regulatory Visual Inspection y Corrosion (Frosio/Nace)

Administrative auditory of installations status

Administrative auditory of installations status

Access & Signalization inspection

Access & Signalization inspection

Foundations inspection

Foundations inspection

Earthing works measurement (Total or Random)

Earthing works measurement (Total or Random)

Structure inspection (corrosion and integrity)

Structure inspection (corrosion and integrity)

Conductors, jumpers & drop lines inspection.

Conductors, jumpers & drop lines inspection.

High Line Division S.L. has developed specific checklists in compliance with the legal regulations provisions, when implemented in our operations, allow us to have solid consistency in the generation of records by allowing our technicians to follow a constant routine during the inspections of high voltage installations, These determine the levels of deviation from a standard established in an Inspection Manual, either provided by the client, or developed by our technical department.

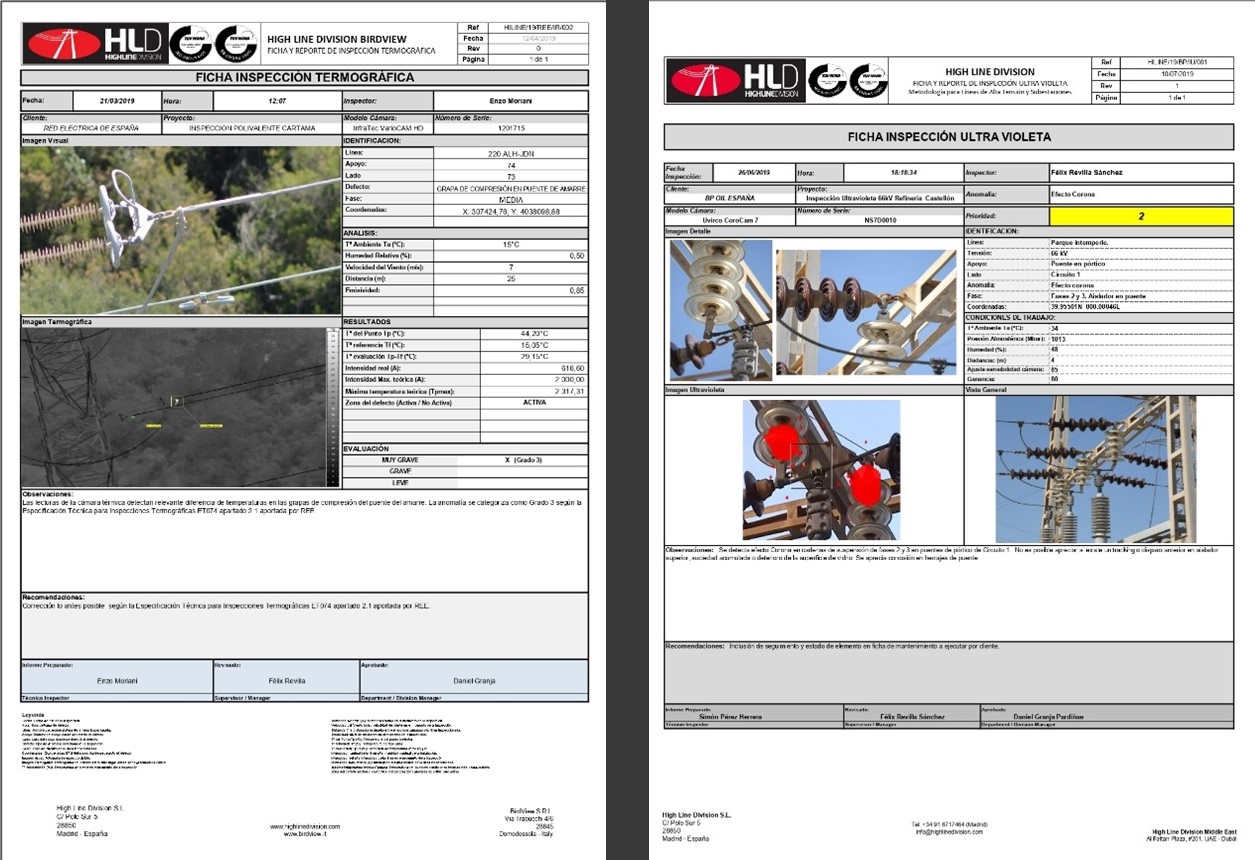

INFRARED & ULTRAVIOLET INSPECTION

Hotspot, corona and partial discharges detection.

Thermal imaging monitoring for hotspot detection

Thermal imaging monitoring for hotspot detection

Ultraviolet inspection for corona and partial discharges detection

Ultraviolet inspection for corona and partial discharges detection

Backoffice analysis for loads computation

Backoffice analysis for loads computation

Reporting

Reporting

High Line Division S.L. has extensive experience in the infrared inspection field. Being a technology adopted since its inception, as well as ultraviolet inspection technology, where we have been the first to integrate a corona camera into drones and aerial auxiliary means, and being a reference in Spain in the use of this technology, counting among its equipment with the most advanced sensors & cameras manufactured by industry leaders in this field (Flir, Ofil, Uvirco...)

Both fields, data capture and office analysis with report generation are supported by our industry experience and the continuous training program of our technicians, along with the use of the state of art equipment and most advanced software, those that guarantee solid, credible, and reliable results in the detection of anomalies and preventive maintenance of facilities.

EARTHING MEASUREMENT

High Voltage Installation Earth Works Measurement

Earthing Works Resistance Measurement

Earthing Works Resistance Measurement

Soil Resistivity and Coupling Measurement

Soil Resistivity and Coupling Measurement

Wiring and Connections Status Monitoring

Wiring and Connections Status Monitoring

Repair & Upgrading

Repair & Upgrading

High Line Division S.L. has certified personnel in earthing measurement directly by the equipment supplier, adding expert technical personnel in construction, maintenance and troubleshooting management in these facilities, including the capabilities for upgrading & improvement works when the measurements obtained are beyond the right parameters.

Our preventive maintenance program includes random control measures on high voltage transmission and distribution lines to guarantee correct ground discharge. If non-conformities are detected, an improvement action appropriate to the environment and the installation is proposed to the client. Another event to consider is vandalism or theft of the valuable material used in the installation that may require quick solution.

SURGE ARRESTERS TESTING & MONITORING

Hotline Inspection of Surge Protection & Insulation

The analysis of the electric field in surge arresters, insulators and other switchgear in substations detects failures in the conductivity of the elements. The testing equipment, once fixed to a universal pole, rests on the element to be inspected, and slides over it allowing the testing probe to detect distortions in the electric field which cause defects in the insulator.

The probe detects and records the distortion indicating the failure. The data is instantly downloaded to a laptop in the field whose management and interpretation is carried out by an electrical engineer, displaying a graph that shows the range of the defect.

Electric field reading and analysis of distortions that may provoke defects

Electric field reading and analysis of distortions that may provoke defects

Hotline Inspection without interruption of service in substations and high voltage lines

Hotline Inspection without interruption of service in substations and high voltage lines

Safety performance since the equipment requires non-conductive contact with the insulators

Safety performance since the equipment requires non-conductive contact with the insulators

Reliable analysis for porcelain and polymeric insulators

Reliable analysis for porcelain and polymeric insulators

Results obtained instantly and visible on laptop via Bluetooth

Results obtained instantly and visible on laptop via Bluetooth

Electric field state graphs for quick decision making

Electric field state graphs for quick decision making

AUXILIARY MEANS FOR AERIAL INSPECTION

The auxiliary lifting means and their integrations have been developed entirely by the Engineering and R&D Department of High Line Division. A military-grade pneumatic telescopic mast with stabilizing legs was used with an effective reach of more than 17 meters from the ground. Featuring a three-axis gyro-stabilizer (Gimbal) fixed to its upper end that, jointly with its integration (RGB 4K + IR + UV), is operated remotely by radio frequency, habilitating both the panoramic rotation and the vertical movement of the Gimbal/camera as well as the complete integration operation such as camera switching, focus, zoom and shooting.

The other differentiating factor is the live streaming capacity of the device, which has a high-resolution video transmission range of more than 10 km and live broadcasts by streaming to a specific server (RTMP, B2B, etc.) or a platform reproduction upon public or private environment (Youtube, Facebook,…).

PneumaticTelescopic Mast (17 meters)

Aerial Equipment Specifications

Aluminium Telescopic Pneumatic Mast with 17 meters height

Aluminium Telescopic Pneumatic Mast with 17 meters height

Set of stabilization legs with safety anchors (in case of heavy winds)

Set of stabilization legs with safety anchors (in case of heavy winds)

DJI Ronin MX three-axis gyrostabilizer

DJI Ronin MX three-axis gyrostabilizer

Integration with photographic, Thermal and Ultraviolet camera

Integration with photographic, Thermal and Ultraviolet camera

Connex Air Unit Full HD-4K Video Long Range Transmitter

Connex Air Unit Full HD-4K Video Long Range Transmitter

Radio Frequency Camera Remote Controller

Radio Frequency Camera Remote Controller

Telescopic Insulating Hotstick (12 meters)

Equipment Specifications

Terex 9-10m Telescopic Insulated

Terex 9-10m Telescopic Insulated

Anti-slip Base

Anti-slip Base

Hotstick Body Harness

Hotstick Body Harness

DJI Ronin M three-axis gyrostabilizer

DJI Ronin M three-axis gyrostabilizer

Integration RGB-IR-UV

Integration RGB-IR-UV

Video Streaming Feature

Video Streaming Feature

Camera Remote Controller

Camera Remote Controller

Radio Control

Radio Control